Anodized vs Cerakote Lower Receivers

If you’ve ever shopped for an AR15, you have surely noticed the terms “anodized and cerakote”. It seems like these coating terms are important enough for manufacturers to mention, but they never actually explain what they are. So for those of you who don’t know which AR15 coating to go with; let's check it out together below.

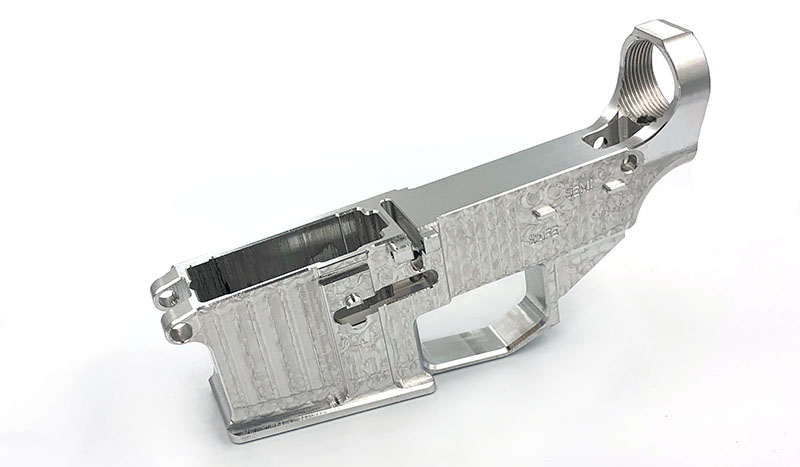

A Raw 80% Lower fresh from a CNC Machine, before anodizing or cerakoting.

What is Anodizing?

By definition, anodizing (sometimes referred to as Hardcoat) is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. In a more comprehensible form, as well as more applicable to our interests; anodizing is the process of taking our aluminum upper, lower, or rail, and dipping it into an acidic bath, where it is then subjected to an electric current, thus making a highly concentrated (and controlled) layer of oxidation on the surface of the aluminum. The anodizing process comes in different grades or ‘types’, withType III being the highest and toughest grade offered in the gun industry.

Benefits of Anodizing a Lower Receiver:

Now that the technical jargon is out of the way, and we understand what anodizing actually is; let's talk about the benefits of Type III anodizing AR15s:

Firstly, and perhaps most importantly; Type III anodizing greatly increases strength, durability, and corrosion resistance. These benefits mean that environmental factors like sticks, rocks, dirt, rain, or snow; as well as dropping, dinging, or submerging your rifle will have far less impact on your rifle’s finish. Anodizing, and Type III anodizing specifically, will make your rifle more durable, so you can focus on the hunt, shot, or task ahead; instead of worrying about the well-being of your firearm.

While protecting the aluminum parts on your rifle, Type III anodizing also has benefits for your rifle’s internals. Because the Type III anodization layer is extremely hard, it cuts down on the coefficient of friction; meaning that even before oil is added, it is more ‘slippery’ than other coatings and lesser level anodization. This reduced friction will allow your gun to cycle more times between servicing, increases the life of the rifles internal moving parts, as well as helps your rifle stay cooler when putting rounds down range at a fast pace.

A Type III Hard Anodized Billet AR15 Lower Receiver finished and ready for milling.

Our Anodized Lower Receivers:

80% Arms offers top of the line anodized lowers for both AR15, AR10, and AR9 platforms available at the links below!

- Type III Hard Anodized Billet AR-15 80% Lower Receiver

- Black Anodized Billet .308 80% Lower Receiver

- Hard Anodized Black AR-9 80% Lower Receiver

One of the most popular colors to cerakote, FDE has really gained in popularity in recent years.

What is Cerakoting?

Cerakoting is the process of applying a liquid ceramic coat to the surface of your firearm. When subjected to extreme heat (putting it in a furnace) the ceramic coating will harden to extreme tolerances, providing your firearm with an incredibly resistant, tough coating. Cerakote applies and dries incredibly thin, so there is no worry about fitment or reliability when putting your gun back together. In fact, there are cerakotes that actually help firearm function, as they cut down greatly on friction between moving parts.

Benefits of Cerakoting a Lower Receiver:

Similar to anodizing, but at a much higher degree; cerakote helps prevent corrosion, improves performance, and reduces wear. You can cerakote an AR15 and feel completely and utterly confident that any environmental factors will not deteriorate, scratch, or mar the finish of your rifle. Cerakote is extremely slick, even more so than anodizing; which will help reduce the coefficient of friction—thus reducing heat and wear on the internals of your rifle.

Unlike anodizing, Cerakoting is also extremely customizable. Any camouflage, color, or design is not out of the question. With all of the specialty Cerakoting companies out there, you can truly give your build the one of a kind look that you can’t just buy off of the shelf.

Unique to Cerakoting, you can actually send off the internals of your build to be coated. Because cerakote is so thin, durable, and most importantly heat tolerant: many people will send off their bolt to be coated. This VASTLY improves durability, and in certain instances can even aid accuracy due to a tighter tolerance.

Our Cerakoted Lower Receivers:

80% Arms offers beautifully finished cerakoted lowers in a variety of colors. More durable than anodizing, this is the highest end finish you can apply to your rifle.

- Flat Dark Earth Cerakoted Billet .308 80% Lower Receiver

- Flat Dark Earth Cerakoted Billet AR-15 80% Lower Receiver

- OD Green Cerakoted Billet AR-15 80% Lower Receiver

- Pink Cerakoted Billet AR-15 80% Lower Receiver

Cerakote consistently wins all durability, lubricity, heat resistance, and endurance tests.

Which AR15 Coating is better?

In short? Cerakote. Anodizing is a perfectly fine finish for anyone (our troops overseas included) but Cerakote offers all the benefits of anodizing at an even higher level, plus the ability to customize color, design, and theme. Cerakote is the most premium coating available to your rifle or pistol, and is often very expensive to do via a third party. If you’re on a budget with your rifle, choose anodizing—as it is a very adequate coating. But if you want a top of the line, best of the best coating in special colors or patterns: Cerakote is your ticket. 80% Arms offers 80 lowers for sale with finishes already applied for the customers ease, so go check out our options and decide what is best for your needs!

Back to List

Back to List