Cut Rifling vs Button Rifling and Cold Hammer Forged Barrels

Ever wonder how your barrel’s rifling was made? You might have also noticed that some people have black barrels, shiny metal barrels or even barrels with custom paint jobs on them. Well today, we’re going to review the most common types of rifling found in firearms and the various types of rifle barrels currently out on the market. The three major types of rifling are made by cut rifling, button rifling and cold hammer forging.

Cut Rifling

Cut rifling is the first rifling method to date which was invented in Germany around 500 years ago. In the photo above, a hook cutter is depicted — This is used in a machine to remove material in a barrel as it creates spiral grooves by passing through the barrel several times.

Although the process itself has not necessarily changed, modern machinery allows barrel makers to conveniently adjust the rifling twist rate as needed while keeping tight tolerances. One of the biggest advantages to cut rifled barrels is that almost no stress is put on these types of barrels during their creation. To this day, cut rifled barrels are still continually used by benchrest and precision shooters. However, due to the time intensive labor it takes just to make one barrel, the machining process is not suitable for scaling up for mass production.

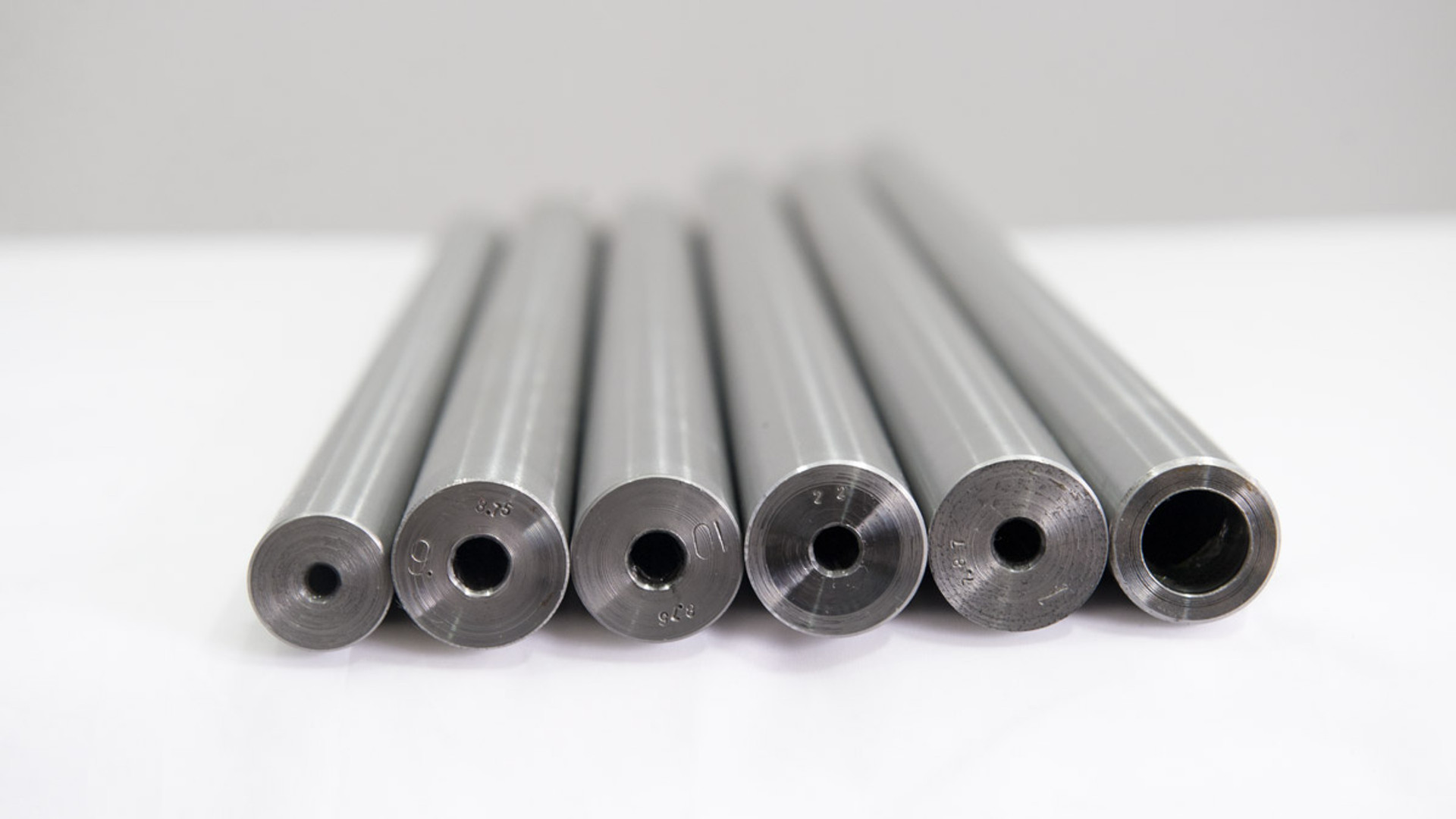

Button Rifling

Button rifling is the most modern and quickest method of rifling that exists for mass production scales. The button rifling process creates grooves in a gun's barrel by utilizing a rifling button. Hence the name — so what is a rifling button used for? A rifling button is an incredibly hard, bullet shaped die made out of tungsten carbide (see image above). This button rifling die has a barrel’s groove profile etched into its surface and it’s done quickly with only a single pass through the barrel.

What does button barrel mean? Well, just about any rifle barrel you buy on the market today probably had its rifling made through button rifling. These barrels can be referred to as ‘button barrels’ but you’re not likely to find them in any product descriptions with online retailers. You’re more likely to see what the barrel’s external or internal coating is made out of.

Is cut rifling better than button rifling?

Although button rifling is the most popular rifling method used in America right now, that’s not to say that there aren’t some downsides to it. These barrels have to be stress-relieved after being rifled to reduce the risk of the barrel splitting or deforming once it has live rounds being fired through it. The pros? Well because you get such consistent bore and groove dimensions these barrels tend to have extreme accuracy. That consistency comes from the manufacturing process’ need to push the rifling button through the barrel only once.

Whereas, with the cut rifling’s manufacturing process, if a single mistake is made while the barrel is going back and forth as the hook cutter is removing material then the whole barrel is a waste and has to be discarded. This could be a serious loss for a smaller shop as it is a time intensive process. However, assuming this doesn’t happen, you get a sub MOA barrel that could definitely last longer than a button rifled barrel. Just be ready to pay a little extra for it.

It’s hard to say which one is really better. It depends on who you ask. If you ask a manufacturer, they might say the button rifling is better because it allows them to make more barrels. But if you ask some shooters with deeper pockets they might opt for the more expensive cut rifled barrel for its longevity and continued performance due to the lack of stress in those barrels. Some may also say that they prefer the more affordable button rifled barrels for their similar levels of performance and will just buy a new one if they have to.

Cold Hammer Forged Barrels

What are hammer forged barrels? Hammer forged barrels refer to barrels that are made through cold hammer forging (CHF). Cold hammer forging involves hammers surrounding all sides of the barrel that hammer down onto the barrel while a ‘mandrel’ is inside of it. This mandrel has a reverse image, or shape, of the desired rifling and twist rate on it. So the rifling within the barrel is created as the hammers do their job.

Other Rifling Types

Cut rifling, button rifling and CHF aren’t the only kinds of rifling out there. Here are some other prominent rifling methods as well! 5R offers the latest and greatest for rifle barrels and polygonal rifling is what’s most often used for handgun barrels.

5R Rifling

5R rifling has become increasingly popular over the past five years and is a step up from conventional rifling patterns. Allow us to explain — conventional rifling will typically have a total of six ‘grooves’ (see figure above). These grooves are quite pronounced but they are also symmetrical so each groove will always be directly across from another groove. There’s a good reason for this and it’s so that it can tightly squeeze the projectile as it passes through, helping it spin and stabilize before exiting the barrel for its flight.

5R rifling improved upon this by instead using five ‘grooves’ and not six. This means that directly across each ‘groove’ is a ‘land.’ Also, each ‘groove’ in 5R rifling is less pronounced than how they are usually made in conventional rifling. With less aggressive ‘grooves’ and more sloped ‘lands’ the barrel doesn’t squeeze the bullet as tight anymore which reduces deformation. It also makes the barrel easier to clean since there is better access to get at the carbon or debris.

Conventional rifling is significantly cheaper to make and buy so it’s not going anywhere anytime soon. Which also means that 5R rifling will remain a pricey upgrade but well worth it for those looking for sub MOA performance out of their AR-style rifles. As an example, Faxon Firearms makes rifle barrels that have 5R rifling. Check out their match series 14.5” .223 Wylde 5R Nitride barrel.

Single Edge Polygonal Rifling (SEP)

Single edge polygonal rifling (SEP) is a proprietary method created by TRIARC Systems which is utilized to create their highly sought after Track 2.0 Barrels. This method combines conventional and polygonal rifling shapes to better retain gas, pressure and reduce bullet deformation to further stabilize the projectile for the flight towards its target. TRIARC also boasts that these barrels will shoot with sub MOA accuracy when using match grade ammunition.

Polygonal Rifling

Polygonal rifling refers to the ‘grooves and lands,’ which can be found in other types of rifling, instead, has ‘hills and valleys’ which are softer or less aggressive. The end result is a polygonal shape when you look through the barrel. This polygonal profile’s shape will typically look like a hexagon or an octagon. Several handgun makers utilize polygonal rifling in their barrels such as Glock, Heckler & Koch, Kahr, etc.

Rifle Barrels

We’ve talked about what’s inside rifle barrels, the rifling, now let’s talk about some additional factors that separate different barrel types from each other such as their manufacturing process or the materials that they are made out of. We’ll be addressing hammer forged barrels, chrome-lined barrels, nitride barrels, stainless steel barrels and CMV barrels.

Are cold hammer forged barrels better?

CHF barrels are known for the best longevity and durability. Cold hammer forged barrels have an advantage in that they can better withstand heat which inevitably leads to a longer service life. Other barrels may be just as accurate and far lighter, but they may not last as long comparatively under constant heat and stress. Symptoms of a barrel degrading or nearing the end of its service may include gas port erosion, throat erosion or loss of accuracy. The average shooter won’t see this happen with a CHF barrel unless they shoot over 20,000 rounds.

Are stainless steel barrels cold hammer forged?

They certainly can be. ‘Cold hammer forged’ actually refers to how the rifling was made for that barrel, not what it looks like on the outside. When we refer to stainless steel barrels we are talking about barrels made out of the steel material identified as 416-R Stainless.

Stainless steel barrels

If you’ve ever made fun of people in the past for having a stainless steel barrel just for its looks, you might want to rethink that in the future. Stainless steel barrels are incredibly useful — they have a heat erosion resistance far superior to chrome-moly barrels and their high resistance to rust almost completely takes away the risk of corrosion in humid climates (which much of the United States can be during the summer and fall months).

The smoother barrel helps it erode and degrade slower which also gives it a longer accuracy life. Above pictured is an 18” stainless steel plus nickel boron barrel. The nickel boron (NIB) is simply the coating on top of the stainless steel barrel. If you don’t like the chrome look this is a good option, or, you can also have the barrel cerakoted in your desired paint color/pattern.

Are stainless steel barrels better than chrome-lined?

Chrome-lined barrels typically come in a chrome moly barrel. Chrome moly barrels and stainless steel barrels will have similar performance results in accuracy. However, chrome moly may not last as long as stainless steel barrels. It’s largely going to depend on what kind of ammo you’re shooting, how bad you’re beating up on your gun and how well you take care of your barrel.

Chrome Lined Barrels vs Nitride Barrels

When it comes to nitride barrel finishes, most people don’t know how big of an umbrella term ‘nitride’ actually is. All these different nitride processes are just different branded terms for very similar nitriding processes. Product descriptions can sometimes be a little scarce on details when it comes to gun components so when you see ‘nitride’ you might be curious to know if they’re referring to black nitride, melonite, ni-corr or salt bath nitride. Regardless of which type of nitride used, it’s a thermochemical process that bonds nitrogen into and onto the barrel itself.

Are chrome lined barrels better?

To be honest, chrome lined barrels and nitride barrels have a very similar lifetime and performance in accuracy when shot in semi-automatic. The advantage in chrome-lined barrels doesn’t really show itself unless you’re shooting in full-auto. Nitride barrels are more resistant to rust but with enough time, heat exposure and moisture, it too can rust. Nothing is 100% rust proof.

Why are chrome-lined barrels less accurate?

Chrome lined barrels are less accurate than nitride barrels because to get a chrome-lined barrel, chrome plating has to be added on top of another material within a barrel’s bore. That chrome plating can diminish the effectiveness of the rifling but the accuracy loss to the average shooter may be completely negligible.

What is CMV?

If you ever see that a barrel is listed as ‘CMV’ that means that it is made out of Chrome-Moly Vanadium which is the mil-spec steel material that was also used to develop and manufacture M16 and M4 rifles from Colt Firearms. CMV has 4150 steel but with the addition of Vanadium that increases its strength, hardness, and overall heat tolerance. All in all, it’s a strong, resilient and durable barrel that can last up to 20,000 rounds.

Start your next AR build with 80 Percent Arms!

With your newfound knowledge about barrels and their rifling, you can choose from our selection of build kits or complete uppers that allow you to select either a parkerized barrel or a stainless steel barrel. Parkerized barrels are simple barrels that have an additional coating on the steel surface which help to provide wear resistance. Let our awesome customer service team know if you need any help choosing parts so that you can have a smooth build process.

Back to List

Back to List